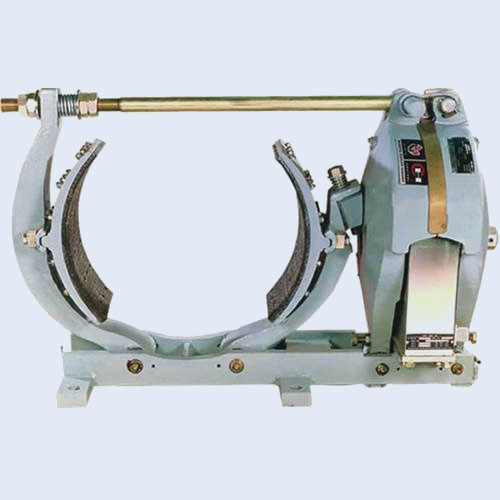

DC Electromagnetic Brakes

BCH electromagnetic shoe brakes confirms to AISE and NEMA Standard. This is designed for heavy industrial and mill duty applications. They are suitable for use with 400, 600 and 800 range mill motors and may also be used in conjunction with other equipments where smooth, rapid and dependable stopping is required. Use of these brakes is extended to hold the load after stopping the hoist, elevator and similar machines.

FEATURES:

Over the wheel design:

Effectively divides the force between the pull rods and pins. Effectively transmit the breaking force to other shoe lever. Provides maximum stopping power with minimum wear of shoe lining. Minimise the bearing wear.

Magnet:

The Magnet consists of two similar magnet steel armature which in conjunction with the coil provides a powerful short stroke magnet system.

Coil

The Epoxy filled class F coil is encapsulated in sheet steel housing for complete environmental protection.

Shoe Lining

Shoe linings are made from special material which has a high co-efficient of friction and low rate of wear. The linings are bolted to the shoes as standard and are easily replaceable.

Shoe Adjustment

Each shoe can be adjusted independently to compensate for the lining wear.

Shoe Positioning

Brake shoe can be positioned to compensate for misalignment of brake to motor shaft / drum thus easing installation.

Torque Setting

The torque is set by turning the torque adjusting nut clockwise to a positive stop and then backing off a preset number of turns to obtain rated torque.

Operation:

Electromagnetic SM brakes are electrically released and spring set. When the coil is energized the armatures are attached together to compress the torque spring and move the shoes away from the wheel, thus releasing the brakes. De-energizing the coil allows the torque spring to separate the armatures and press the shoes against the wheel. Setting the brake thus making it fail safe in the event of power failure.

TYPES AND DUTY RATING:

SM Brakes are basically of two types: Shunt brake and Series brake

Shunt:

Shunt brakes have their coils separately energized from a DC source of AC source when used with rectifier. Shunt brakes are rated in Voltage for intermittent or continuous duty. The recommended duties are

- Intermittent duty

- Continuous Duty

Series Brake:

Series brake have their coils in the armature circuit of a DC motor. These brakes are rated in amperes for ½ hour and 1 Hour corresponding to rating of DC series motors. The recommended duties are:

One Hour or Mill Duty

Half hour or Crane Duty