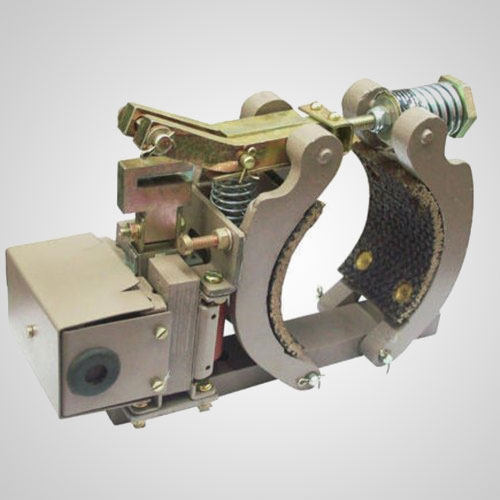

CONSTRUCTIONAL FEATURES:

Special constructional features such as those listed below account for exceptionally long mechanical life of the brakes.

(i) Neoprene shock absorbs-prevents link pin breakage and increases the life of the solenoid.

(ii) Hardened steel lever and spring gland – the hardened steel construction of the lever and spring gland

reduces wear at the pins and all other points of contact.

(iii) Cast iron wheel – The physical properties of the iron minimize the tendency of the wheel to deposit

metal particles in the lining which could result in serious scoring of the wheel.

(iv) Spring pins – The tight gripping spring pins insure against the loss of pins due to shock.

(v) inexpensive lining replacement – Lining attached to shoes by removable flat head groove- pins.

(vi) Fever joints – The shoe is actually a part of the shoe lever and not separate from it. This makes for

fewer mechanical joints and keeps wear points at a minimum.

(vii) Solenoid – The solenoid coil can be removed with out disturbing the brake adjustment. Solenoid

loading is designed to reduce wear.

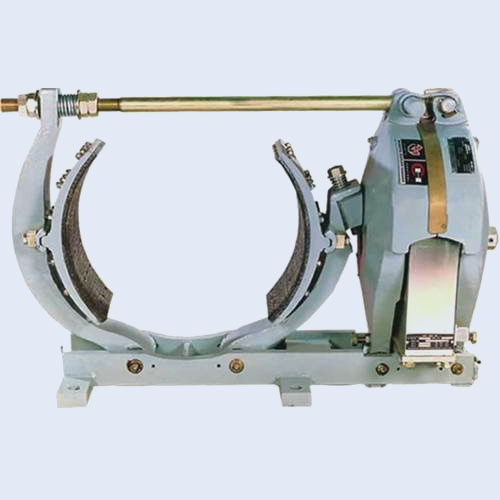

ADJUSTMENTS:

Adjustments for torque and lining wear are conveniently and quickly made. Braking torque and lining wear adjustments are made at the top of the brake. A set screw and locking nut located on the top of the solenoid frame provide adjustment for equalizing clearance between the brake shoes to prevent dragging when the brake is released.

AC SOLENOIDS:

The remarkable efficiency of Bhartia Industries Limited’s AC Solenoids ( Pull Type) encourages application to wide range of purposes requiring a definite pull motion under automatic or distant control in connection with electrically driven machinery.

Typical functions includes the operation of electro-mechanical brakes and valves, various short stroke motions on machine tools and many operations required in automatic machinery of all kinds.

SPECIFICATIONS:

The solenoid consists of laminated frame and plunger with steel supporting frame. The epoxy moulded coil is held in place by means of flat steel springs to prevent transmission of shock to the coil. The plunger and frame are carefully machined to ensure quiet operations. Solenoids can be used for up to 600 operations per hour if the pull-in-time is within specified limits. These solenoids are provided with fixing holes for floor mounting.